The participants in the meeting discussed the retooling of defence-industry enterprises, the development and consolidation of the national machine-tool sector, as well as state industrial policy in the area of modernising the engineering sector.

Dmitry Medvedev’s introductory remarks:

Meeting on measures to develop the national machine-tool sector for modernising the military-industrial complex

As you might guess, our meeting deals with the development of the machine-tool sector, which is certainly the most important element of the Russian economy. The engineering sector has always ensured major demand for feedstock and materials in affiliated economic sectors, and it has also encouraged demand for new, high-tech products and modern technology. And, of course, it has provided work for companies in the most diverse Russian regions.

By the way, consumption of all types of machine-tool equipment has increased by 13% throughout 2012 as compared to 2011, and this consumption has reached certain levels. At about $3 billion, I cannot say that these levels are anything fantastic, but this is a substantial amount already.

However, the overall performance of the machine-tool sector can hardly be considered very encouraging. Russia ranks between the top 20 and top 30 manufacturers of metalworking equipment. Everyone knows who the leaders are: Germany, Japan and now China. The Russian machine-tool sector accounts for 0.03% of the national GDP. For China, Japan and Germany, it is almost 1% of GDP. This exceeds Russian levels almost 100 times over.

Dmitry Medvedev: "Сonsumption of all types of machine-tool equipment has increased by 13% throughout 2012 as compared to 2011."

The share of computer numerical control (CNC) machine-tools is only about 10%. It is common knowledge that the Russian domestic market relies heavily on imports, an estimated 90%, according to experts. We must by all means rectify the situation. And the fact that we have gathered at the Stankin Moscow State Technological University speaks volumes. I have just finished inspecting their centre, which is, certainly, quite good and impressive. To accomplish this breakthrough, we must make substantial efforts. For instance, we must promptly upgrade our defence-industry companies and supply the Armed Forces with additional amounts of modern and high-tech equipment. I will not frighten everyone with the wear-and-tear statistics of old equipment. You are well aware of this: defence-industry equipment is over 20 years old, on average.

In the near future, in 2015-2017, the defence industry will require metal-cutting machine-tools, press-and-forging equipment and other machine-tools worth an estimated 100 billion roubles annually. Actually, this 100 billion roubles a year is the same as the $3 billion that I mentioned.

Dmitry Medvedev: The sector’s advanced-development projects are capable of facilitating a technological breakthrough. Certainly, this includes the human-resources potential as well as research and development projects.

The sector’s advanced-development projects are capable of facilitating a technological breakthrough. Certainly, this includes the human-resources potential, which is our most substantial asset, as well as research and development projects, which I have just seen (the laboratory complex “Proving Ground – Pilot Production Facility” of the Stankin Engineering Centre). Of course, there are other sites as well. We need to convert these advanced-development projects into actual achievements, so that Russian machine-builders would be able to start manufacturing modern world-class equipment.

Colleagues, I would like to note a few more important aspects, and then I will open it up to you. First, we must concentrate assets in accordance with various programmes, including the federal targeted programme National Technology Base. Incidentally, we have already accomplished a lot under this programme. Indeed, we are making impressive headway in the so-called breakthrough areas, including research and development work, investment projects and the most promising technologies.

Second, we must expand the list of machine-tool products being purchased under a special procedure. I would like to know what you think on this score, because this is, of course, always a double-edged sword. But I am talking about the high-priority purchases of products by defence-industry companies, provided that they are not inferior to their foreign equivalents in terms of price and quality. This is a matter of expert assessments. And, of course, we must ensure the effective implementation of this decision. I would like to remind you that we have a special resolution, which was passed in 2011, and which stipulates bans and restrictions on the import of foreign-made products during the awarding of contracts for the delivery of products, the execution of works and the provision of services for national defence needs.

Dmitry Medvedev: We must ensure permanent technological audits of equipment and engineering solutions being acquired for defence-industry projects, and we must also improve the relevant procedure for the delivery of machine-tools and related equipment.

And, third, we must ensure permanent technological audits of equipment and engineering solutions being acquired for defence-industry projects, and we must also improve the relevant procedure for the delivery of machine-tools and related equipment. This is quite important. I have just had it rather convincingly explained to me that a considerable share of imported equipment functions based on solutions being adopted in other countries, including the procedure for switching on machine-tools. This ensures our complete dependence on these solutions. If all this flows through the global network, then everyone understands that this supply route can be cut off anytime. And this, of course, is a matter of our technological independence. This is what I wanted to say in the beginning.

<…>

***

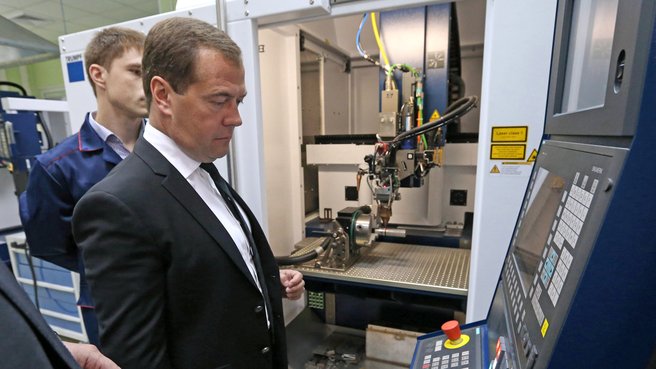

Before a meeting at the Stankin Moscow State Technological University, Dmitry Medvedev visits the university’s State Engineering Centre

Visiting Stankin University’s State Engineering Centre

Prime Minister Dmitry Medvedev was shown a number of foreign and Russian machine tools and the component parts they help produce. Mr Medvedev also watched as a robotised device cut a steel pipe.

Dmitry Medvedev reviewed a unit for robotised production training. In addition to Stankin University students, upper-level pupils are being trained here, which provides them with the foundations for their future engineering education.

The Prime Minister visited a robotic production lab where he reviewed a range of Russian robots created jointly with AvtoVaz. These robots are currently used in car manufacturing.

Dmitry Medvedev was also shown a unique numerical control system which can operate a robot using a special programme, and a 3D-base. Russian scientists created the 3D-base in just two years. Currently there are only ten or so programmes like it in the world.

Finally, Dmitry Medvedev reviewed the conveyor that can function without human control for several days. He was also shown a hydroabrasive treatment centre where large, solid component parts can be cut under pressures reaching 6,000 atm.

***

Following the meeting, Minister of Industry and Trade Denis Manturov took reporters’ questions

Transcript:

Question: What kind of proposals did the Ministry of Industry and Trade make to the Prime Minister?

Denis Manturov: Our enterprises are driven by the existing targeted programme to develop and manufacture innovative machine-tool products through a consolidated government order.

Denis Manturov: Our proposals regarding the expansion of our machine-tool industry are first and foremost about amending Government Resolution No. 56 of 2011. This resolution encouraged our machine-tool companies to supply their products to customers from other industries. However, our machine-tool enterprises were not manufacturing certain products at a time when the decision was made. Thus, we proposed amending the resolution and expanding the list of products that are now being made in Russia for purposes of public procurement or, to be more precise, whose capital costs are covered by the state budget. Our goal is to start buying these products from Russian manufacturers rather than foreign. This year, we will be completing the first phase of the machine-tool industry’s expansion programme. We have developed a fairly wide range of products that will soon go into production, so the enterprises are counting on orders by industrial associations and the defence industry as the latter proceed to upgrade their production floors.

Question: It has already been mentioned that the defence industry enterprises are using fairly worn-out machine tools. Are there any plans to dispose of them?

Denis Manturov: No. We can, of course, use disposal programmes in all our industries, but I don’t think that it’ll do us any good. I believe that our enterprises are driven by the existing targeted programme to develop and manufacture innovative machine-tool products through a consolidated government order. Such an order will be put together under several federal targeted programmes, primarily, the federal targeted programme for the defence industry which provides for major purchases of machine tools. Of course, we hope that import restrictions (this is not inconsistent with WTO rules as they relate to the public sector) will also provide an additional incentive for our machine-tool enterprises.

Speaking about a scenario without the participation of the state, our enterprises have orders worth at least 150-200 billion roubles until 2020 which will ensure the minimum growth of the Russian machine-tool industry at 30%-35% a year. This is fairly impressive growth, but we have set ourselves even more ambitious goals. We consider establishing joint ventures, developing our own production capacities for new projects through Stankin’s State Engineering Centre and the system integrator facility which was recently created by Russian Technologies at Oboronprom’s subsidiary companies, which will consolidate orders for enterprises run by Russian Technologies during the modernisation projects. So, I think that our current activities plus corporate decisions to be taken in the future will further promote purchases of competitive Russian-made machine tools.

Denis Manturov: Our enterprises have orders worth at least 150-200 billion roubles until 2020 which will ensure the minimum growth of the Russian machine-tool industry at 30%-35% a year. This is fairly impressive growth, but we have set ourselves even more ambitious goals.

Question: Let me clarify something. Do the orders to 2020, which will provide for up to 35% growth, come from the defence industry alone or does that number include all Russian industry?

Denis Manturov: I'm talking about the orders placed by Russian industry as a whole. Eighty percent of this amount will come from defence enterprises.

Thank you.